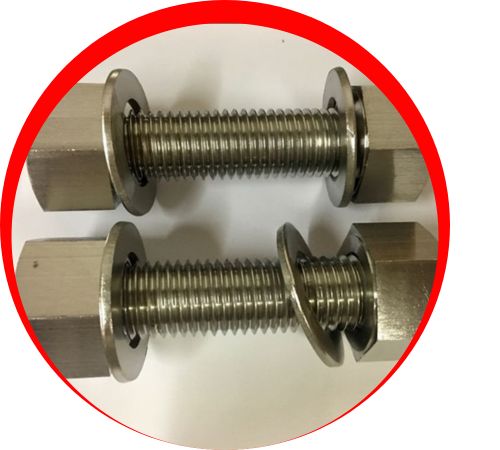

Bristow Nickel Alloys is a reliable producer and dealer of top-class nickel alloy products in Midland, UK. We deal in Inconel 625 stud bolts which are renowned for their exceptional strength, corrosion resistance and elevated temperature performance. These stud bolts are used for enduring extreme conditions. To guarantee top quality we perform stringent testing, such as chemical composition analysis, mechanical testing, hardness testing, and ultrasonic inspection. Our rigorous quality control processes ensure that all Inconel 625 stud bolts meet industry expectations of reliability, strength, and long-term performance.

Inconel 625 stud bolts are made of Nickel (58% minimum), Chromium (20-23%), Molybdenum (8-10%), Niobium (3.15-4.15%), along with trace amounts of Iron, Carbon, Manganese, Silicon, and Aluminum, giving them superior strength and resistance to corrosion. These stud bolts have superior mechanical properties, such as tensile strength of 860 MPa (125 ksi), yield strength of 414 MPa (60 ksi), and a minimum elongation of 30%, which provide high durability. Inconel 625 stud bolts have a density of 8.44 g/cm³ and a melting point of 1290-1350°C, providing superior thermal stability, oxidation resistance, and reliability in harsh environments.

| Specification | ASTM F468, B166 / ASME SF468, SB166 |

|---|---|

| Size | M02 to M33, Custom Sizes |

| Length | 3 mm to 200 mm |

| Stud Bolt | UNF, BSW, BSF, METRIC, UNC, or as required |

| Standard | DIN 525, DIN 835, DIN 938, DIN 939, DIN 940, DIN 949-1, DIN 949-2, DIN 975, DIN 976, DIN 2509, BS 2693, BS 3692, BS 4439, IS 1862, IS 13178, ANSI/ASME B18.31.2, ANSI/ASME B16.5 |

| Form | Hex, Threading, Square, Round as per Gauge Etc. |

| Threads Configuration | ASME B1.1 2A/3A – 2B/3B Inch Unified Threads and B1.13M 6h-6G Metric Coarse Threads |

| Certification | Dual Certified As per ASTM & ASME Codes |

| Types | Stud Bolts, Fully Threaded Stud Bolts, Tap End Stud Bolts, Double End Stud Bolts, Stud Bolts with Reduced Shank, Reduced Shank, Flange Stud Bolts, Flange Bolting, Weld Studs |

| Threads | Unless otherwise specified, the threads shall be rolled or cut and tapped horizontally or vertically |

| Test Certificate | as per EN 10204 / 3.1 Manufacturer Test Certificate |

| Additional Certifications | PED 97/23/EC Certified, Merkblatt AD 2000 W2 Certified |

| Production process | M24-M100: hot forging, M2-M24: Cold Froging, for custom-made connecting element machining and CNC |

| Head drive of Stud Bolts | Six-Lobe, Phillips, Phillips/Slot, Slotted etc |

| Packing of Stud Bolts | IN BULK: canton, pallet, Small Boxs / carton / pallet, or customer request |

| Surface Coating | Ptfe Coated Phosphate Coating Teflon Coating Zinc Coating Hot Dipped Galvanizing Coating Cadmium Coating Xylon Coating |

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

| Inconel 625 | 0.10 max | 0.50 max | 0.50 max | 0.015 max | – | 5.0 max | 58.0 min | 20.0 – 23.0 |

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Inconel 625 | 8.4 g/cm3 | 1350 °C (2460 °F) | Psi – 1,35,000 , MPa – 930 | Psi – 75,000 , MPa – 517 | 42.5 % |

Bristow Nickel Alloys is the biggest manufacturer and supplier of Inconel 625 Stud Bolts in Midland, UK. With high-quality, long-lasting, and corrosion-resistant products. Precision and reliability are ensured through our advanced manufacturing technology. We maintain industry standards and supply products on time with excellent customer service. Focused on quality and innovation, we supply reliable solutions to address the changing requirements of our customers.

Contact us to get a quick quote for your requirement.

Inconel Alloy 625 Stud Bolts are used extensively in harsh environments where there is a high need for high-strength, corrosion-resistant, and heat-resistant properties. They are well suited to fasten components in marine, aerospace and chemical processing equipment where there is exposure to seawater, acids, and high temperatures. The stud bolts are also used for heat exchangers, power plants, and furnace applications because of their superior oxidation and stress corrosion resistance. Their durability and long-lasting performance make them a first-choice option for stringent engineering and industrial applications that necessitate exceptional strength and reliability.